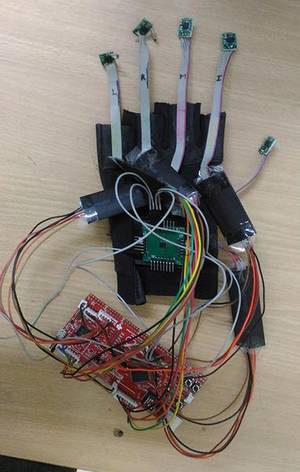

15 sensors that help gather data on kinematics or hand motion

A data glove, which measures the individual joint angles of all the five fingers to understand the activity of daily living, developed by Nayan Bhatt, Research Scholar from the Department of Applied Mechanics, IIT Madras, recently won the Budding Innovators Award given by the Delhi-based National Research Development Corporation (NRDC). Mr. Bhatt has been working on developing models for studying finger kinematics for the past three years.

The data glove has 15 sensors (plus an additional reference sensor) that help in gathering information about kinematics or hand motion. The sensors are placed on the segments of a finger — each finger has three segments and the junction between two segments forms a joint. Each sensor is connected to a microcontroller board using a flexible wire to collect data.

“The sensors measure the joint angles through the change in orientation information. We are interested in gathering information about motion of the fingers excluding the wrist,” said Mr. Bhatt. “In the case of people with Parkinson’s disease, the data glove will provide information about hand kinematics and help clinicians assess the severity of disease. It will complement the traditionally used Universal Parkinson’s Disease Rating Scale.”

Avoiding deformation

The development may find application in animation and other industries.

Unlike in the case of the conventional data glove, the sensors are placed directly on each segment of the finger to avoid any deformation. “We placed the sensors directly on the segments of fingers as the use of cloth like in a traditional data glove can hinder natural movements and also cause slippage or deformation,” he said.

Efforts are on to reduce the number of sensors used. “We will first use all the 15 sensors to perform some training postures, which will then be used for developing an algorithm that will reduce the number of sensors used. Currently, with the machine learning algorithm developed by Mr. Bhatt we can use as few as eight sensors. We want to reduce it to six,” said Dr. Varadhan S.K.M. from the Biomedical Engineering Division of the Department of Applied Mechanics, IIT Madras.

“We are using the prototype to develop products for speech-related disability,” Dr. Varadhan said. “By using specific movements of a finger for specific words, the data glove can help speech-disabled people to communicate. We can use a speech synthesiser and speaker to generate sound.” Work has to be done to first map specific words to specific movements of the finger.

21 angles

One finger can move in different directions. So the total number of joint angles is about 21. Sensors have been used to sense all the 21 angles. “Ten predicted angles have large errors of more than two degree, and the remaining angles have less than 2 degree error. The average is five degrees. In a few months, with advanced algorithms, we might be able to reduce the average prediction error to two-three degrees,” Dr. Varadhan said.

source: http://www.thehindu.com / The Hindu / Home> Sci-Tech> Technology / by R. Prasad / Chennai – April 26th, 2017